In the realm of manufacturing, innovation is a driving force that continually shapes and transformsindustries. One such groundbreaking innovation that has revolutionized manufacturing processes is 3D printing, also known as additive manufacturing. This article explores the profound role of 3D printing in manufacturing and its impact on efficiency, customization, and the overall landscape of production.

Introduction to 3D Printing

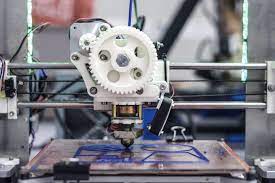

At its core, 3D printing is a process that involves creating a physical object layer by layer from a digital model. This method contrasts with traditional subtractive manufacturing, where materials are cut, shaped, or molded from larger pieces. 3D printing offers a more precise and resource-efficient approach, opening up new possibilities in the manufacturing domain.

Rapid Prototyping and Product Development

One of the key advantages of 3D printing is its ability to facilitate rapid prototyping. Manufacturers can quickly create prototypes of products and iterate designs without the need for extensive tooling or molds. This accelerates the product development cycle, enabling companies to bring new ideas to market faster and with reduced costs.

Customization and Personalization

3D printing enables a level of customization and personalization that was previously impractical. Manufacturers can produce highly tailored components or products to meet specific customer requirements. This shift towards personalized manufacturing allows for a more responsive and customer-centric approach, catering to individual preferences and needs.

Complex Geometries and Intricate Designs

Traditional manufacturing methods often face limitations when it comes to producing complex geometries or intricate designs. 3D printing eliminates many of these constraints by building up structures layer by layer. This capability is particularly advantageous in industries such as aerospace and healthcare, where intricate and lightweight components are crucial.

Reduced Material Waste

Traditional manufacturing processes often generate significant material waste due to subtractive methods and the need for molds or dies. In contrast, 3D printing is an additive process, meaning material is deposited only where needed. This reduction in waste not only contributes to sustainability efforts but also translates into cost savings for manufacturers.

On-Demand Production

The on-demand nature of 3D printing disrupts traditional inventory models. Instead of maintaining large inventories, manufacturers can produce items as needed. This just-in-time manufacturing approach minimizes storage costs and reduces the risk of overproduction, offering a more agile and efficient production model.

Tooling and Production Flexibility

Traditional manufacturing often requires the creation of specialized tools, molds, or dies for each product. 3D printing eliminates the need for extensive tooling, allowing for quick and cost-effective changes in production. This increased flexibility is especially beneficial for small-batch or custom production runs.

Cost-Effective Prototyping and Small-Batch Production

With 3D printing, the costs associated with prototyping and small-batch production are significantly reduced. Traditional methods may involve expensive tooling and setup, making small runs economically unfeasible. 3D printing eliminates these barriers, making low-volume and customized production more accessible.

Advancements in Material Options

The range of materials available for 3D printing has expanded dramatically, including plastics, metals, ceramics, and even composite materials. This broad selection allows manufacturers to choose materials that best suit the specific requirements of their products, further enhancing the versatility of 3D printing in various industries.

Integration with Digital Technologies

3D printing seamlessly integrates with digital technologies such as computer-aided design (CAD) and simulation tools. This interconnected digital workflow streamlines the entire manufacturing process, from initial design to the production of the final product. The synergy between 3D printing and digital technologies enhances precision and efficiency.

Conclusion

As technology continues to evolve, the role of 3D printing in manufacturing becomes increasingly prominent. From rapid prototyping and customization to reduced material waste and on-demand production, 3D printing is reshaping the way products are designed and manufactured. Embracing this innovative technology not only enhances efficiency but also opens up new possibilities for creativity and sustainability in the manufacturing landscape. As industries continue to adopt and adapt to 3D printing, its transformative impact on manufacturing is poised to grow even further.