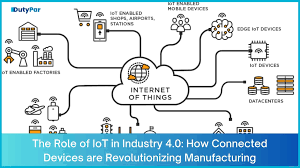

Industry 4.0, often referred to as the fourth industrial revolution, represents a paradigm shift in manufacturing driven by the integration of digital technologies, automation, and data analytics. At the heart of Industry 4.0 is the Internet of Things (IoT), which enables interconnected devices and systems to communicate, collaborate, and optimize manufacturing processes in real-time. The adoption of IoT in manufacturing is revolutionizing the industry, leading to increased efficiency, productivity, and competitiveness.

Smart Manufacturing

Advantage: IoT enables the creation of smart manufacturing environments where machines, sensors, and production systems are interconnected and communicate seamlessly. This connectivity allows for real-time monitoring, analysis, and optimization of production processes, leading to improved efficiency and resource utilization.

Predictive Maintenance

Advantage: IoT sensors embedded in manufacturing equipment can collect data on machine performance, operating conditions, and wear and tear. This data is analyzed using predictive analytics algorithms to forecast equipment failures and schedule maintenance proactively, reducing downtime and costly repairs.

Supply Chain Optimization

Advantage: IoT enables end-to-end visibility and traceability in the supply chain by tracking raw materials, components, and finished products throughout the manufacturing process. This visibility allows manufacturers to optimize inventory management, streamline logistics, and ensure timely delivery to customers.

Quality Control and Assurance

Advantage: IoT sensors and actuators can monitor and control product quality parameters in real-time, detecting defects or deviations from specifications early in the production process. This proactive approach to quality control minimizes waste, reduces rework, and ensures consistent product quality.

Remote Monitoring and Management

Advantage: IoT enables remote monitoring and management of manufacturing operations, allowing managers and engineers to access real-time data and insights from anywhere, at any time. This remote visibility enhances decision-making, troubleshooting, and collaboration across geographically distributed facilities.

Challenges and Considerations

While the IoT offers significant advantages to manufacturing, several challenges and considerations must be addressed:

- Data Security and Privacy: IoT devices and networks are susceptible to cybersecurity threats, including data breaches, malware attacks, and unauthorized access. Manufacturers must implement robust security measures to protect sensitive data and intellectual property.

- Interoperability and Standardization: The proliferation of IoT devices and platforms from different vendors can lead to interoperability issues and compatibility challenges. Standardization efforts are needed to ensure seamless integration and communication between disparate systems and devices.

- Scalability and Integration: Scaling IoT deployments across large manufacturing facilities or complex supply chains requires careful planning and integration with existing IT infrastructure and legacy systems. Manufacturers must consider factors such as scalability, compatibility, and interoperability when implementing IoT solutions.

- Data Analytics and Insights: While IoT generates vast amounts of data, extracting actionable insights and value from this data requires sophisticated analytics capabilities. Manufacturers must invest in analytics tools and expertise to derive meaningful insights and drive continuous improvement initiatives.

Conclusion

The Internet of Things (IoT) is transforming manufacturing operations and driving the evolution of Industry 4.0. By leveraging IoT technologies for smart manufacturing, predictive maintenance, supply chain optimization, quality control, and remote monitoring, manufacturers can achieve greater efficiency, productivity, and agility in today’s competitive landscape. However, addressing challenges such as data security, interoperability, scalability, and data analytics is essential to realizing the full potential of IoT in manufacturing. With strategic planning, investment, and collaboration, manufacturers can harness the power of IoT to drive innovation, sustainability, and growth in the digital age.